Precision Engineering – High-Quality Fabrication – Global Export Capability

In modern mechanical and industrial manufacturing, sheet metal products play a vital role across a wide range of applications. From automotive and electronics to construction, furniture, and household appliances, sheet metal is the foundation for countless components and structures. As technology evolves, sheet metal fabrication has become more accurate, flexible in design, and stronger in durability.

We proudly specialize in custom sheet metal fabrication and export, delivering high-quality products that meet international standards. Trusted by partners across Asia, Europe, and North America, our company is committed to precision, consistency, and innovation in every project.

1. Overview of Sheet Metal Products

Sheet metal refers to thin, flat pieces of metal that are formed through industrial processes and used in a wide array of mechanical, electrical, and structural applications. These materials—ranging in thickness from 0.5mm to 10mm—can be cut, bent, punched, and welded into nearly any shape or configuration.

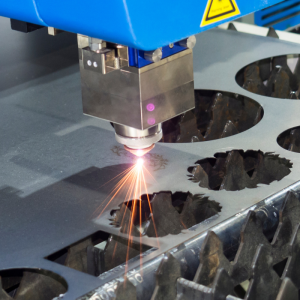

Our sheet metal products are fabricated from high-grade raw materials using advanced technology such as laser cutting, CNC punching, precision bending, MIG/TIG welding, powder coating, and more. We ensure:

-

Accurate dimensions

-

Tight tolerances

-

Smooth, clean surfaces

-

Strong and reliable structures

2. Key Sheet Metal Product Categories

We manufacture a wide variety of customized sheet metal products, including but not limited to:

Industrial Components:

-

Machine enclosures, control cabinets, electrical panels

-

Pump covers, inverter boxes, safety shields

Electrical & Electronics:

-

Device enclosures, cable trays, circuit board mounts

-

Brackets, racks, and precision sheet components

Automotive & Transportation Parts:

-

Mounting brackets, underbody panels, fenders, guards

Home & Office Furniture:

-

Metal cabinets, wall-mounted shelves, furniture frames

-

Kitchen accessories, storage units, modular racks

Construction & Architecture:

-

Decorative panels, railing systems, awnings, partitions

-

Metal accessories for light-steel frame buildings

3. Materials and Thickness Range

We work with a wide range of high-quality materials to meet various industry needs:

-

Stainless Steel (SUS 201/304/316): corrosion-resistant, durable, aesthetic

-

Galvanized Steel (GI/EGI): anti-rust, cost-effective, good strength

-

Aluminum: lightweight, corrosion-resistant, excellent heat dissipation

-

Copper / Brass: high conductivity, decorative appearance

-

Cold-Rolled / Hot-Rolled Steel (SPCC, HRP): robust and machinable

Material thickness ranges from 0.5mm to 10mm, depending on the application and structural requirements.

4. Manufacturing Process – Modern Fabrication Technology

Our production facility is equipped with cutting-edge machinery and a streamlined, automated workflow to ensure efficiency and quality at every stage:

-

CNC Laser Cutting: High-speed, ultra-precise edge cutting

-

CNC Punching & Stamping: Accurate holes, embossing, or indentations

-

CNC Bending/Forming: Precise angles and dimensions to spec

-

MIG/TIG Welding & Robotic Welding: Strong, clean welds with consistency

-

Powder Coating, Surface Finishing, Plating: Protective and aesthetic finishes

-

Assembly and Export-Grade Packaging: Ready-to-ship units or subassemblies

Each process is monitored under strict quality control protocols to ensure compliance with your technical drawings and tolerance specifications.

5. Quality Commitment – Export Standards

We implement a strict ISO 9001:2015 certified quality management system, with inspection checkpoints throughout all phases of production:

-

Dimensional accuracy with tolerances under ±0.1mm

-

Stable structures and non-deformable joints

-

Burr-free edges and clean finish

-

Surface uniformity and durable coatings

-

Export-compliant packaging for international logistics

Our sheet metal products are trusted by clients in Japan, Korea, Germany, the USA, Thailand, and the Middle East, where high precision and compliance are required.

6. Real-World Applications of Sheet Metal

Sheet metal fabrication supports a wide variety of industries and sectors:

-

Manufacturing & Automation: machine bodies, conveyor systems, enclosures

-

Electrical Systems: distribution boxes, switchgear cabinets, panel frames

-

Construction & Architecture: ventilation panels, custom façades, steel frameworks

-

Furniture & Fixtures: desks, chairs, cabinets, modular components

-

Transport & Vehicles: brackets, guards, structural panels

Whether for heavy-duty industry or lightweight consumer products, sheet metal enables both functionality and customization.

7. Why Choose Us for Sheet Metal Manufacturing?

✅ Nearly a decade of experience in sheet metal manufacturing and export

✅ Fully equipped facility with in-house design, engineering, and production

✅ Skilled workforce of engineers and trained technicians

✅ Rapid prototyping and mass production capability

✅ Strict quality control and on-time delivery

✅ Competitive pricing with outstanding customer support

We partner with OEM/ODM clients, contractors, and distributors to deliver tailor-made solutions that align with specific industry demands.

8. Request a Quote or Consultation Today

Are you looking for a trusted partner in sheet metal fabrication for international projects or large-scale production?

Whether you need custom parts, full assemblies, or development from your 2D/3D CAD drawings – we’re ready to help.